Cigar Accessory Design: Form Follows Function

People ask me why? Why did you make the Stinky Cigar® ashtray? Ok, yes, there was a reason. After the “Cigar Boom” of the 1990’s during the early 2000’s, we were meeting to smoke cigars after work once a week (on Wednesday evenings). I did not like the mess and litter on the tables. It occurred to me that the real problem was the little cigarette ashtrays most pubs and lounges used for their smoking customers . . . even us cigar smokers. The ashtrays were too small. Even the places that DID have a few cigar-ashtrays, their cigar-ashtrays were too shallow or had a tiny bowl for the ashes . . . certainly no room for the typically large cigar butts. The ashtrays would quickly fill up. Especially with a group of 8 to 12 guys smoking a cigar or two!

Apparently, most waitresses don’t like to empty ashtrays. They would prefer to spend their time serving drinks which directly impacts their odds of earning more tips! Now that I think about it, most waitresses didn’t like the cigar smoke, let alone carrying an ashtray full of stinky cigar butts over to the trash can! The table(s) would become littered with cigar bands and cellophane and the ashtrays were full or overflowing. As an admitted neat nick, I wanted a solution for the mess.

I went online and searched for a larger cigar ashtray. The only ashtrays I could find were typical, shallow, ceramic ashtrays. When we tried bringing our own cigar ashtrays, the real problem didn’t go away. The ashtrays would fill up with cellophane, bands, matchsticks, ash, cigar butts, and the occasional cocktail napkin. What was worse, all the litter placed in the (shallow) ashtrays would prohibit placing a lit cigar on the cigar-rest. Nobody wants to set their burning cigar (the lit end) on cellophane or paper of any sort. The ashtrays were inadequate for our group.

One of our favorite places to gather on Wednesday nights was downtown in the Main Street Station’s steakhouse. Because the Hotel Casino was themed with old railroad trains, they had a 1920’s Pullman Car setup on the side of the lobby for customers waiting to be seated in the steakhouse. They also used that old Pullman Car as their smoking area. They had mostly cigarette ashtrays and only a few tiny glass cigar ashtrays. The tiny glass cigar ashtrays were like a tapered glass brick. The bowl was only 2 ½” by 3” by 1” deep and they were really heavy! . . . 3 ½ pounds each! These glass cigar ashtrays were quite common at the time, but the bowl just didn’t hold much.

The executive chef at Main Street Station was a cigar connoisseur, and he made sure they sold an assortment of popular cigars out of a humidor cabinet in the steakhouse lobby. One night I went out to the lobby and asked the hostess for a soup bowl. She was supposed to take drink orders and serve drinks to their guests waiting in the Pullman car, but she rarely waited on us. She didn’t like the cigar smoke and would avoid going into the Pullman car. In her typical indignant attitude, she asked; “Why?” I explained how the soup bowl would be used to empty the over-filled cigar ashtrays. She said “Oh.” . . . turned and walked away. I grabbed some drinks at the bar (for me and my cigar buddies) and went back into the Pullman car wondering if she would let us use a soup bowl.

About 20 minutes later, she walked in with a standard ‘office’ trash can (black hard-rubber) with a plastic trash-can-liner. Without saying anything, she reached over to the table, grabbed each ashtray full of ash & cigar butts and dumped each one into her little black trash can, set the trash can behind my chair and left. I said thank you, but what I really wanted to say: “Don’t you think this is a fire hazard?” I kept an eye on the bucket for a while. We didn’t know if some of those ashtrays had lit or smoldering cigar butts. My search for a solution continued.

During that period of time, I stopped by a Salvation Army (second hand) Store and found an old brass bowl with 3 bear claw feet. Eventually I took it to Main Street Station the next time we went for a cigar-night. It was such a good (design) match for the old retro railroad train theme . . . I just left it on the luggage rack (over the seats) for several months. Like a large soup bowl, it worked just fine. And it looked good on the antique style table. Years later, I added some cigar stirrups and now keep it in my office on the back bar where I cut & light my cigars.

Eventually my first attempt to satisfy the need for a larger ashtray was not really an ashtray! It was a 2-gallon galvanized bucket. We had a galvanized Corona Beer Bucket on our patio, and I thought that would make a handy receptacle to dump the little cigarette ashtrays during our weekly Herf (herf means to gather with others to enjoy fine cigars). My wife did not want to give up the Corona Beer bucket, so I bought one at Lowe’s. The galvanized bucket would work well because it was fireproof and could hold plenty of cellophane, cigar butts and trash. But it looked like a little garbage can. For decorations, I cut out cigar images from my piles of cigar catalogs and spray glued the cigar images all over the outside of the galvanized bucket.

Everybody liked the decorated galvanized Butt Can. It became the topic of discussion during the night. They ended up calling it “The Stinky Butt Bucket” and we had a lot of laughs. Problem was: It was a trash can and the guys kept putting it up on the table. If we’re going to put something on the table, I think it should look nicer. More importantly, it should have a place to set your cigar down while you tip the waitress. All the while, I had an old, silver-plated bowl setting on my patio that I found in a second-hand store a couple years earlier. It seemed like a good size for a large cigar ashtray, but it needed something to hold cigars. While staring at that silver-plated bowl for many months, it occurred to me that some souvenir coins would be just the right size to hold a cigar. The next time I was in a casino (the Monte Carlo), I walked by the kid’s video game arcade that had a souvenir coin machine! It would take 4 quarters and smash one into a souvenir coin. After making 3 oval coins, I thought that would be enough. Couple days later, I drilled a block of wood with a 1 ¼” auger bit, cut the block in half and used a broom stick (and hit it with a hammer) to bend the souvenir coins to the right direction. Then I grabbed the old, silver-plated bowl and the 3 souvenir coins and set out to find a jewelry repair shop to solder the coins onto the rim of the bowl. While searching for a jewelry shop in the downtown area, I pulled into a radiator repair shop we had done business with. One of the guys agreed to solder the 3 coins onto the rim of my silver-plated bowl. I gave him $5.00 and a couple of bundle cigars I had with me. The first Stinky Cigar (mockup) Ashtray was born.

I took it home and buffed the scorch marks out of the metal surfaces. That was a Wednesday, so it went with me to the Wednesday evening ‘herf’ at a PT’s Pub. This pub was one of our favorites because it had a seating area with comfortable couches, padded chairs and coffee tables. The new shinny bowl caught the eye of everyone who showed up that night and quickly became the topic of discussion! After the initial question: “What is THIS?” and many ensuing comments like: “Where’d you get it?” as the alcohol kicked in, the jokes and wise cracks started flying! Naturally they called it the “Stinky Ashtray” and said I should make more. I said: “No! It’s too much work!”

After many weeks of very positive and complimentary comments, I started wondering if this big metal ashtray might sell in the current cigar community marketplace. While the design was very unique and evolved from a need that was of interest to me, it occurred to me that this is a good design concept. My college education was (Bachelor of Science) in Industrial Design. We were always taught: “Form Follows Function.” Before you attempt to make something look pretty, it must first FUNCTION properly and efficiently. As I was being encouraged by friends as well as people I knew in the cigar business, I focused on the functionality of a large metal ashtray. Several of the local cigar store owners and managers encouraged me to move forward with the project. One guy was Bill Sooley, the manager of the Paiute Tribal Smoke Shop. We had become friends and he passionately encouraged me to move forward with the project.

My career had always been in construction management. At that time, I was “between jobs” waiting for the next construction project to start up. There was plenty of time for me to research how to manufacture a metal cigar ashtray and examine the potential with real world data, prices and costs. All aspects of a new product needed to be researched and evaluated. The first area was manufacturing. Where should I look? USA? China? Viet Nam? Google? As I was poking around the internet, I found a factory in Mumbai, India. They had a form on their website to submit a request for pricing. So: What the heck . . . filled out their form and explained what it was and how big it needed to be. I didn’t have a drawing, so I just sent a few photographs of my unique Silver-plated bowl with souvenir coins soldered to the rim. I told them that I think it should probably be made of stainless steel. We started corresponding by e-mail.

We asked each other a lot of questions. We went back and forth for the next several weeks. One question they wanted to know was about the “finish” on the stainless-steel bowl. Would you like it to have a Brushed finish or a highly polished (shinny) finish? Based on my Industrial Design training, I thought the highly polished finish would be more functional and easier to clean. All my questions were answered. It was time to get their production cost. Finally, they gave me their cost to manufacture this eight-inch stainless steel bowl with a base and three stirrups. The unit cost was extremely low! However, for the unit price they quoted, they wanted to run 15,000 pieces! And there were no “terms” for payment! All cash, up-front! I choked on the initial investment!

I shared the information with my best friend, Ken. He was always very wise and had good sense. He listened. His advice would change my world. He suggested contacting the SBA (Small Business Administration) and take advantage of their free consulting services for small businesses. He also said to ask for a consultant who has experience in the ‘import’ business. Seemed like a good idea. I called the SBA immediately. My first appointment was with an import export executive named Allen Bell. He was retired and volunteered his time for the SBA but only worked one day per week. Mr. Bell worked out of the North Las Vegas office of the SBA and I lived in the South East (Henderson) part of the valley. No problem! I have the time and I can drive.

Of course, I brought the Silver-plated mockup to show him. Our first meeting was very productive. After telling the story about this unique cigar ashtray, he answered all my questions and gave me an overview of the manufacturing and import process I was about to attempt. He also gave me a detailed “homework” assignment. My “homework” was to find and contact import brokers. He gave me a list of questions to ask each import broker, including their field of specialization, setup requirements, rates, fees, etc. During the meeting, he seemed to be a little aloof or disinterested or possibly a little condescending. He told me about a class he teaches for “first-time” business owners (or managers) who want to learn more about the manufacturing and import process. He gave me a copy of his course curriculum and syllabus. When our time was up, I thanked him and asked to setup our next meeting for the following week. He said no! “Not until you do your “homework” and read that syllabus! I insisted that it would be no problem because I was between jobs and had a whole week to make the phone calls. He reluctantly said ok and: “Make an appointment with the receptionist. BUT! . . . Don’t come back if you haven’t read that syllabus and completed all the research on import brokers!”

My motivation to make the calls was very high. This (import broker) information was very important to analyzing the financial feasibility of the project. The Internet was fairly new so using the Yellow Pages (printed phone books) was the easiest way to find and contact import brokers. I spent the next few days calling and following up with import brokers Finally after several days of taking copious notes, the information was ample for his homework parameters and requirements. There were several pages of detailed notes on a yellow legal-size tablet for the follow up meeting.

Our second meeting also went very well. He seemed much nicer and expressed his satisfaction as he reviewed the homework assignment (notes). I’ll never forget his compliment! He said: “You’re going to be successful.” I was so surprised (and pleased)! I asked him: “Why do you say that?” He told stories about many of his clients that do not want to “do the work” and even ask him to give them the answers or even make the calls because they don’t feel comfortable asking questions about services that they know nothing about. He shared several examples and ended with his summary. He said: Anybody can have a container load of product manufactured and imported (if you have the money). The REAL challenge is to be able to sell it after it arrives. Again, he shared examples of people who thought they have something that would sell and got stuck storing a container load of product. In each case, they ended up liquidating the products at a tremendous loss. Not only did they make no profit, but they didn’t even recover their initial investment.

We met several more times. Almost every week. By this time, I had a lot of respect for his experience. While I was pretty sure this unique metal cigar ashtray would sell, I wasn’t completely convinced or that I should “bet” over thirty thousand of my own dollars on it! We discussed the risk factors and the reality of what the market would actually be. Then, he gave me the most profound advice. He told me to order samples first. This made a lot of sense. He went on to explain how typical this is in the manufacturing process and how it all works. After all, I already had a production price from the factory. But the price was based on a photograph and a brief description sent by e-mail. He encouraged me to order samples and pay the costs including molds and express shipping. My goal was to have samples to show at the annual cigar convention at the end of the summer. It was already May, and these things take time.

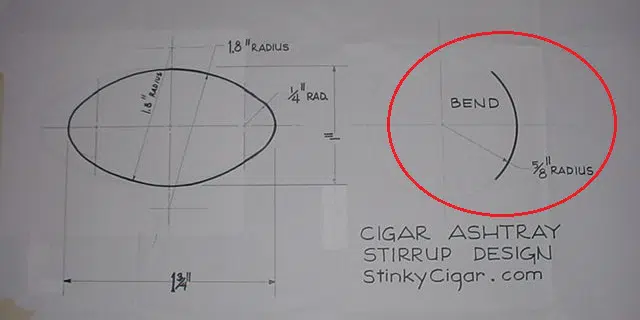

The first sample showed up in about 45 days! Just one stainless steel sample and it was all wrong! I was shocked and appalled. Mostly disappointed. The stirrups were WAY too big! The rim was WAY too wide! The bowl was too small. Before contacting the factory, I made a drawing with dimensions. I specifically wanted the stirrup to be the right size and shape. I showed the (miss made) sample to the SBA consultant and he suggested I send the changes to the factory and ask for another ‘corrected’ sample. Problem was a shortage of time. The cigar convention was only a few months away. He suggested I make sure the factory had all the information and review the samples with photographs. Before ordering a production run, he suggested I ask the factory for a “Pre-Production Case” to see the product as well as the actual packaging they would be shipped in. Wasting no time, I ordered a case of 36 samples and transferred the money immediately.

To be continued: Off to the Show! 2004 RTDA

Checkout our floor standing ashtray or our Facebook page.